Substructure and Superstructure in Building Construction

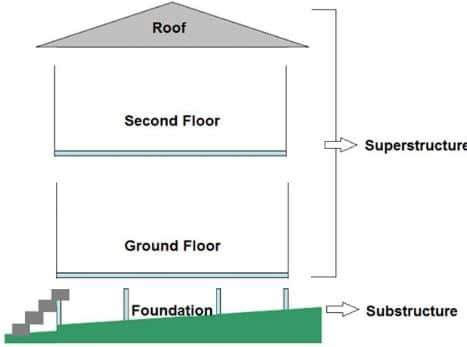

In building construction, projects are divided into two main components: the substructure and the superstructure. Each part plays a crucial role in the overall structural integrity and functionality of the building.

Superstructure

The superstructure is the part of the building that is constructed above ground level. It serves the primary purpose of facilitating the intended use of the structure and includes the following elements:

– **Columns**: Vertical load-bearing members designed to support the weight of the structure above.

– **Beams**: Horizontal members that distribute the load from the superstructure evenly across supporting columns or walls.

– **Slabs**: Flat, horizontal surfaces that form floors or ceilings.

– **Finishes**: Materials applied to surfaces for aesthetic or protective purposes, such as paint or cladding.

– **Door and Window Schedules**: Detailed plans outlining the placement, dimensions, and specifications of doors and windows.

– **Flooring**: Surface materials covering the ground-level areas.

– **Roofing**: The structure and materials that make up the overhead covering of the building.

– **Lintels**: Horizontal supports that span openings like doors and windows.

– **Parapets**: Low protective walls at the edge of a roof or balcony.

Substructure

The substructure is the portion of the building constructed below ground level. Its primary function is to transfer loads from the superstructure to the soil, ensuring stability and preventing settlement. Key elements of the substructure include:

– **Footings**: Structural components that distribute the load from the superstructure to the soil beneath.

– **Plinth**: The base or platform upon which the superstructure is erected, serving as a transition between the foundation and the building proper.

Roles of Structural Engineers

Structural engineers play a pivotal role in the planning and execution of both the substructure and superstructure. Their responsibilities include:

– **Generating Plans and Specifications**: Creating comprehensive plans and specifications for the substructure, considering soil conditions, building requirements, and local regulations.

– **Calculating Stresses and Loads**: Determining the structural requirements to ensure the building can withstand anticipated forces and environmental conditions.

– **Incorporating Structural Elements**: Designing support beams, columns, and foundations to fulfill their intended functions and uphold the building’s stability.

Differences between superstructure and substructure of a building

| Superstructure | Substructure | |

| Location | Constructed above ground level | Constructed below ground level |

| Purpose | Facilitates building’s intended use | Transfers loads to supporting soil |

| Elements | Walls, columns, beams, doors, windows, etc. | Foundations, plinth |

Detailed Analysis of Substructure and Superstructure

Superstructure Components

1. **Columns**:

– **Function**: Support vertical loads and transfer them to the foundation.

– **Materials**: Commonly made from concrete, steel, or wood.

– **Design Considerations**: Must be designed to resist compression and potential buckling.

2. **Beams**:

– **Function**: Distribute loads horizontally to columns or walls.

– **Materials**: Typically constructed from steel, concrete, or wood.

– **Design Considerations**: Must be designed for bending and shear forces.

3. **Slabs**:

– **Function**: Provide flat surfaces for floors and ceilings.

– **Materials**: Usually made of reinforced concrete or composite materials.

– **Design Considerations**: Must be designed for flexural strength and serviceability.

4. **Finishes**:

– **Function**: Provide aesthetic appeal and protection to structural elements.

– **Types**: Includes paint, plaster, tiles, and cladding.

– **Design Considerations**: Selection depends on environmental exposure and aesthetic requirements.

5. **Doors and Windows**:

– **Function**: Provide access, light, and ventilation.

– **Materials**: Commonly made from wood, aluminum, PVC, or steel.

– **Design Considerations**: Must be designed for thermal performance, security, and aesthetics.

6. **Flooring**:

– **Function**: Cover and protect floor slabs, providing a finished surface.

– **Materials**: Includes tiles, wood, vinyl, carpet, and laminate.

– **Design Considerations**: Must be durable, easy to maintain, and aesthetically pleasing.

7. **Roofing**:

– **Function**: Protect the building from weather elements.

– **Materials**: Commonly made from shingles, tiles, metal sheets, or membranes.

– **Design Considerations**: Must be designed for water resistance, thermal performance, and wind loads.

8. **Lintels**:

– **Function**: Support loads over openings like doors and windows.

– **Materials**: Typically made from concrete, steel, or stone.

– **Design Considerations**: Must be designed for bending and shear forces.

9. **Parapets**:

– **Function**: Provide safety and protection at the edge of roofs or balconies.

– **Materials**: Commonly constructed from masonry, concrete, or metal.

– **Design Considerations**: Must be designed for structural integrity and aesthetic integration.

Substructure Components

1. **Footings**:

– **Function**: Distribute structural loads to the soil.

– **Types**: Includes strip footings, pad footings, and raft foundations.

– **Design Considerations**: Must be designed based on soil bearing capacity and load requirements.

2. **Plinth**:

– **Function**: Transition between foundation and superstructure, elevating the building above ground level.

– **Materials**: Commonly made from reinforced concrete or masonry.

– **Design Considerations**: Must be designed for durability and resistance to moisture.

Integration and Coordination

The integration of the substructure and superstructure requires meticulous coordination to ensure the overall stability and functionality of the building. Structural engineers must work closely with architects, contractors, and other stakeholders to address various factors:

– **Load Path**: Ensuring a continuous load path from the superstructure to the substructure and ultimately to the ground.

– **Material Compatibility**: Selecting materials that work well together and meet the structural and environmental requirements.

– **Construction Sequencing**: Planning the construction process to ensure each component is built in the correct order and manner.

– **Regulatory Compliance**: Adhering to local building codes and regulations to ensure safety and legality.

Conclusion

The harmonious integration of the substructure and superstructure forms the foundation of any building project, epitomizing the meticulous coordination and expertise of structural engineering. By comprehensively understanding each component’s function and significance, stakeholders can navigate the complexities of construction with clarity and precision. Ensuring the stability and integrity of both the substructure and superstructure is essential for the safety, durability, and functionality of the building.